ANALYSIS OF DEFECTS IN MANUFACTURING OF PRESSURE DIE CASTING

Abstract

Author(s): Ratnesh Kumar Dewangan, AmitVishvakarma, Ashish Kumar Khandelwal

The manufacturing defects of the Die casting samples were decrease the strength and quality of product. In this project a systematic approach has been developed to find the best process for manufacturing die-casting. Form the survey different type of parameter has been taken to manufacture the die casting parts which has to analyses the influence of process parameters on the defects during Die casting of aluminum alloy. Tests carried out on nine design of experiment characterized by different survey on the basis of Temperature, Force exerted by piston and Type of casting process on aluminum alloy that solidify and analysis the defects of shrinkage and porosity due to gases produce during cooling. In this work defects initiation and growth have been analyzed in order to identify the factors causing these very high residual stresses that often produce shrinkage and porosity propagation throughout the casting. The defects were found on every square centimeter by microscope and then take their average. The best outputs were obtained on the basis of results of confirmation experiments reveal that topsis method can effectively optimize an optimal combination of the process parameters. It is perhaps the first attempt of its kind in the area of die-casting which analyze manufacturing parameter, and is expected to be of significant interest and value to the industry.

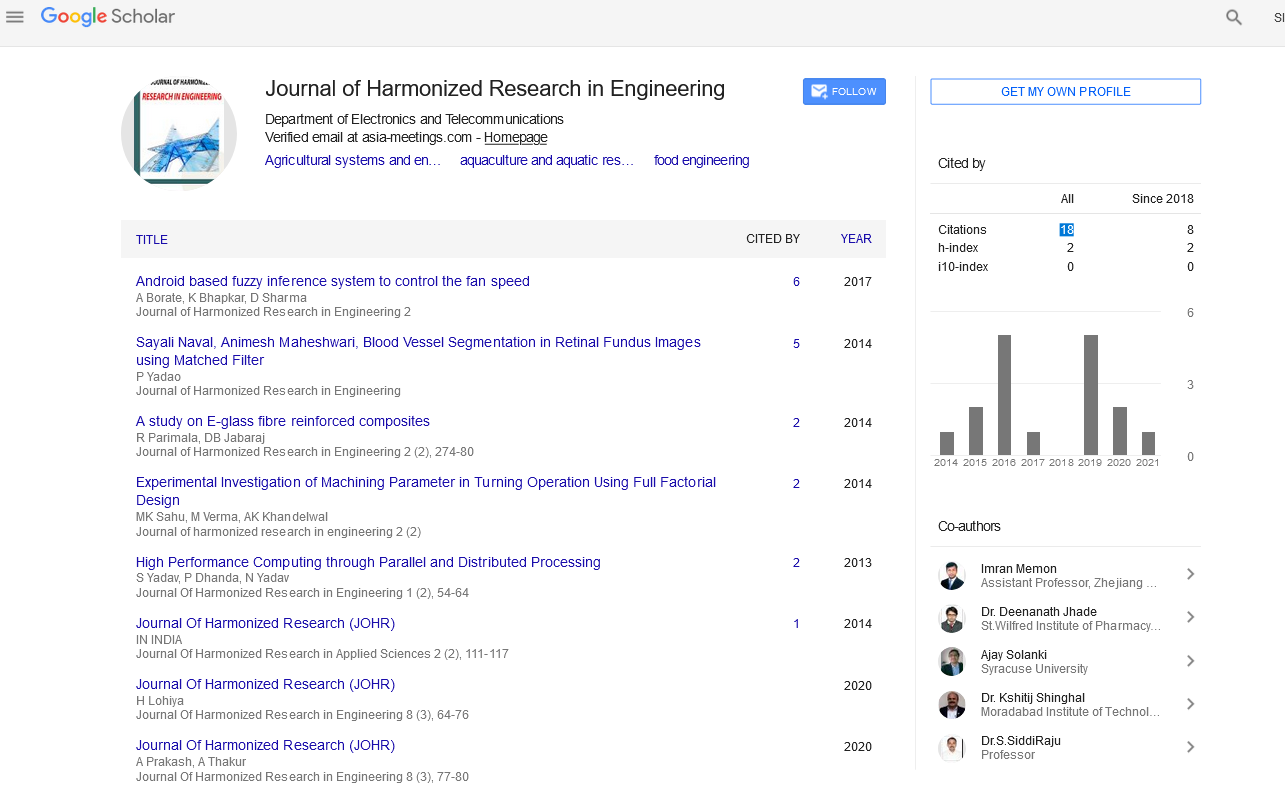

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report