ANALYSIS THE MACHINING EFFECT ON CFRP MATERIAL USING AJM

Abstract

Author(s): Satyendra Singh, S P Shrivas, Sailesh Dewangan

An effort evaluates the advantages offered by non-conventional machining for the development of composite fiber reinforced polymer material (CFRP). Although, abrasive jet Machining (AJM) is highly efficient in the machining of advanced composite materials due to their unique characteristics, efficient machining of sandwich structures by AJM needs many challenges to be addressed. This work presents various issues observed in AJM on CFRP composite materials, and the effects of AJM are analyzed in processing these composite materials. In the AJM process used drilling experiment was done on glass as the work piece and aluminum oxide (Al2O3) as abrasive powder. The effect of Overcut (OC) and Material removal rate (MRR) of glass material was finding by using L9 orthogonal array based on Taguchi design and considering the, pressure of air and stand-off-distance are control parameter.

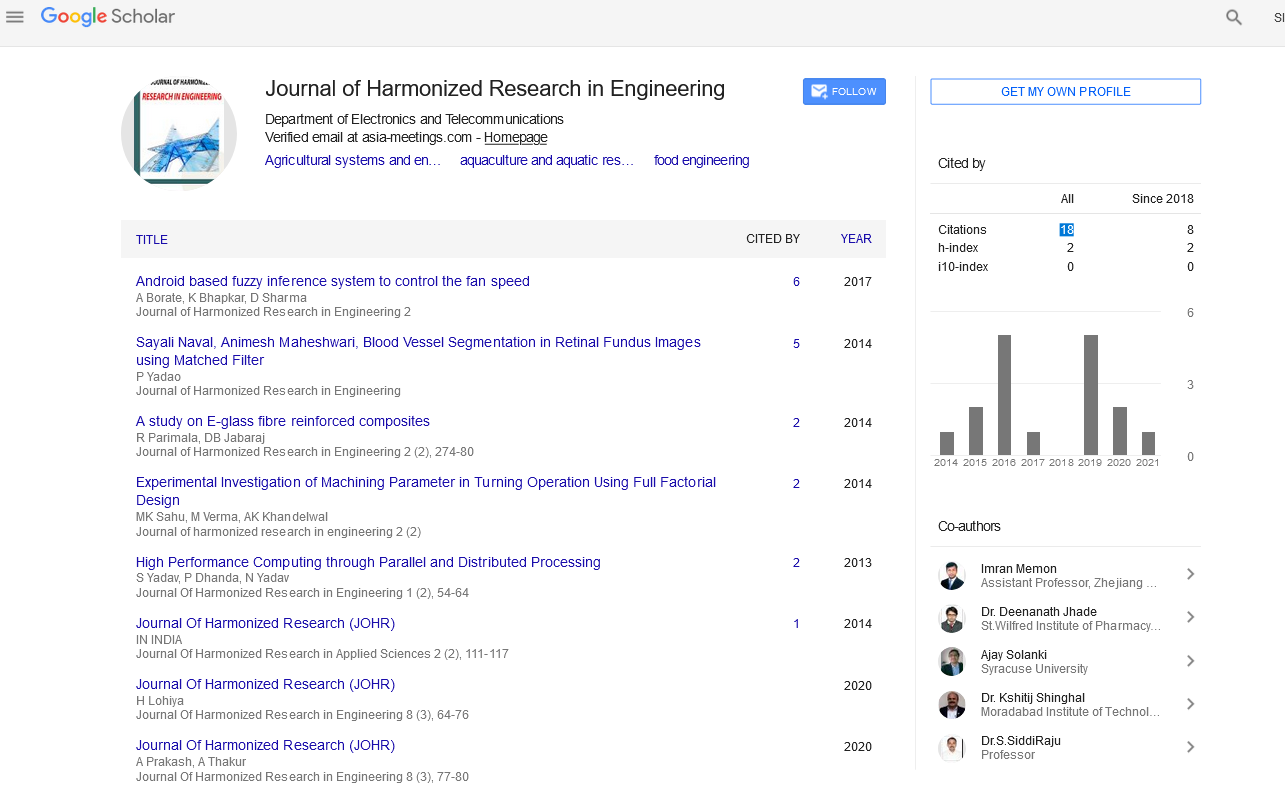

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report