ESTIMATION OF SURFACE QUALITY IN MACHINING OF HARDNED MATERIAL USING COATED CARBIDE TOOL

Abstract

Author(s): Rajendra Kumar Patel, Ashish Kumar Khandelwal, Manish Verma, Girish Gupta

In this study, an attempt has been made to evaluate the performance of multilayer coated carbide inserts during dry turning of hardened AISI 4340 steel (47 HRC). The effect of machining parameters (de pth of cut, feed and cutting speed) on surface roughness parameters (Ra and Rz) were investigated by applying ANOVA. The experiments were planned basedon Taguchi’s L27orthogonal array. Results showed that surface roughness parameters (Ra and Rz) are mainly influenced by feed and cutting speed, whereas depth of cut exhibits minimum influence on surface roughness (Rz) and neglegible influence in case of surface roughness (Ra). The experimental data were further anlyzed to predict the optimal range of surface roughness parameters (Ra and Rz).

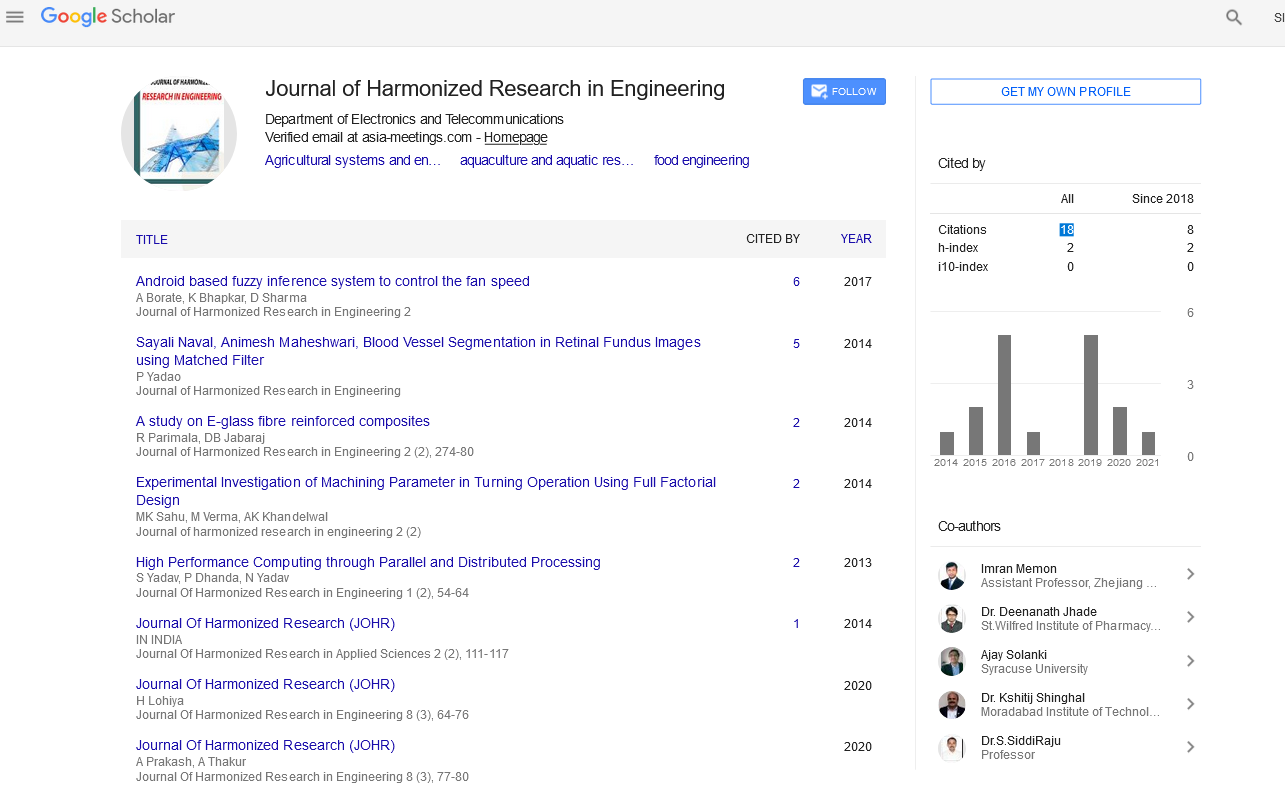

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report