MULTI-OBJECTIVE OPTIMIZATION OF MACHINING PARAMETERS USING GREY TAGUCHI METHOD

Abstract

Author(s): Amar Nath, S.P.Shrivas, A K Khandelwal

In this research, a distinct combination of Taguchi method, Gray Relational Analysis (GRA) with an experimental investigation was conducted to determine the main machining parameters which contribute to material removal rate (MRR) and surface roughness (SR) in wire-EDM of mild steel. In WEDM operations, Proper selection of process parameters is essential to obtain good surface finish and higher MRR. In setting the machining parameters, particularly in rough cutting operation, the goal is - the maximization of MRR, minimization of SR or increasing the quality. In this experiment using the selected control parameters are discharge current, pulse on time, pulse off time and servo feed setting. The four control parameters each are three level means L27 orthogonal array based on Taguchi design is selected for this analysis. The relatively significant parameters were determined by Analysis of Variance (ANOVA). The variation of output responses with process parameters were mathematically modeled by using non-linear regression analysis. The models were checked for their adequacy.The optimal parameter setting for maximum MRR and minimum SR was obtained by Gray Relational analysis. Keywords: Material removal rate (MRR), Surface roughness (SR), ANOVA, Taguchi Design, Grey Relation Analysis (GRA).

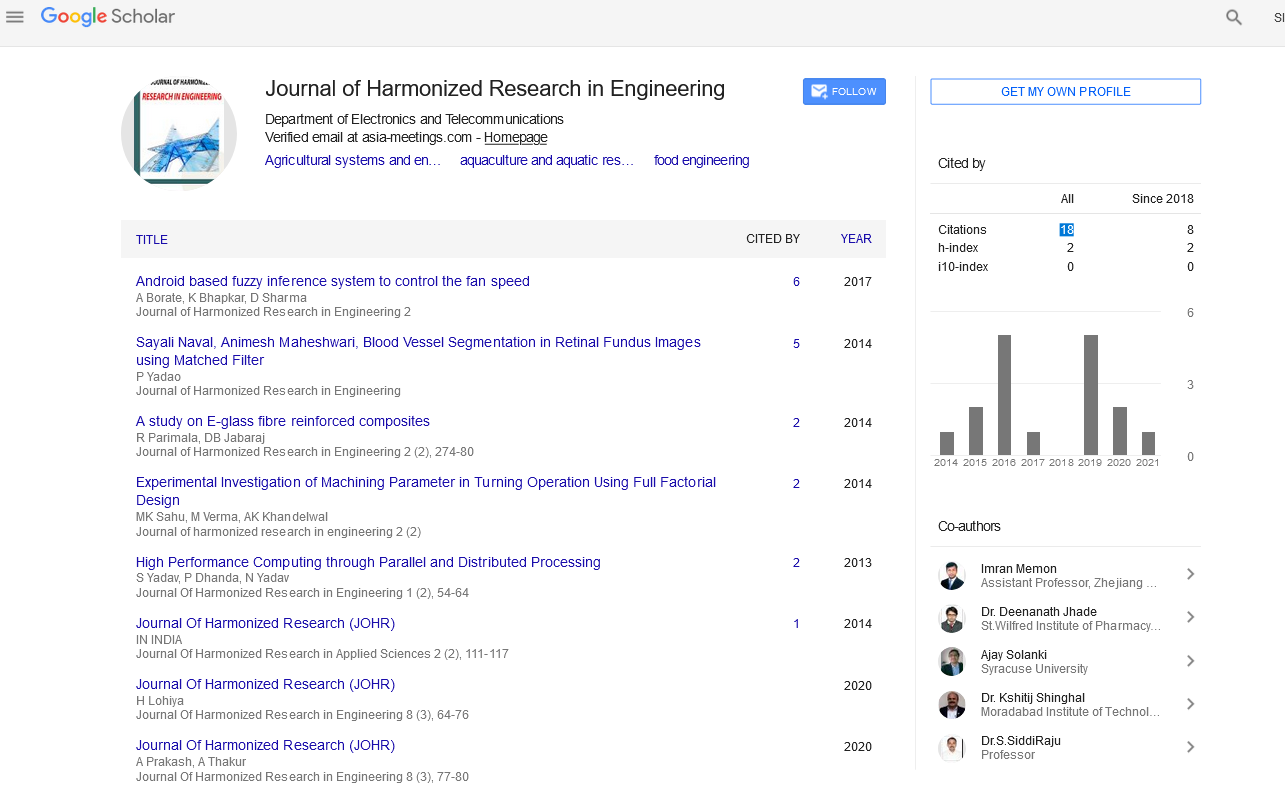

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report