OPTIMIZATION OF FAILURE IN MACHINE PARTS BY HYBRID METHOD

Abstract

Author(s): Rakesh Soni, Vivek Kumar Sharma, Piyush Tiwari

During the operation of these machine tools, different kinds of failures are faced by the industry. CNC machines into groups helps maintenance department to focus their attention to the machine that h as high tendency to produce defect. A field failure analysis of computerized numerical control (CNC) lathes is described. Field failure data was collected over a period of one year on approximately ten CNC lathes. A coding system to code failure data was devised and a failure analysis data bank of CNC machine was established. The failure position and subsystem, failure mode and cause were analyzed to indicate the weak subsystem of a CNC lathe. If the machine producing the defect is inspected late, the damage caused might be large. Moreover, to remove this problem Hybrid method is use to identify machine failure.

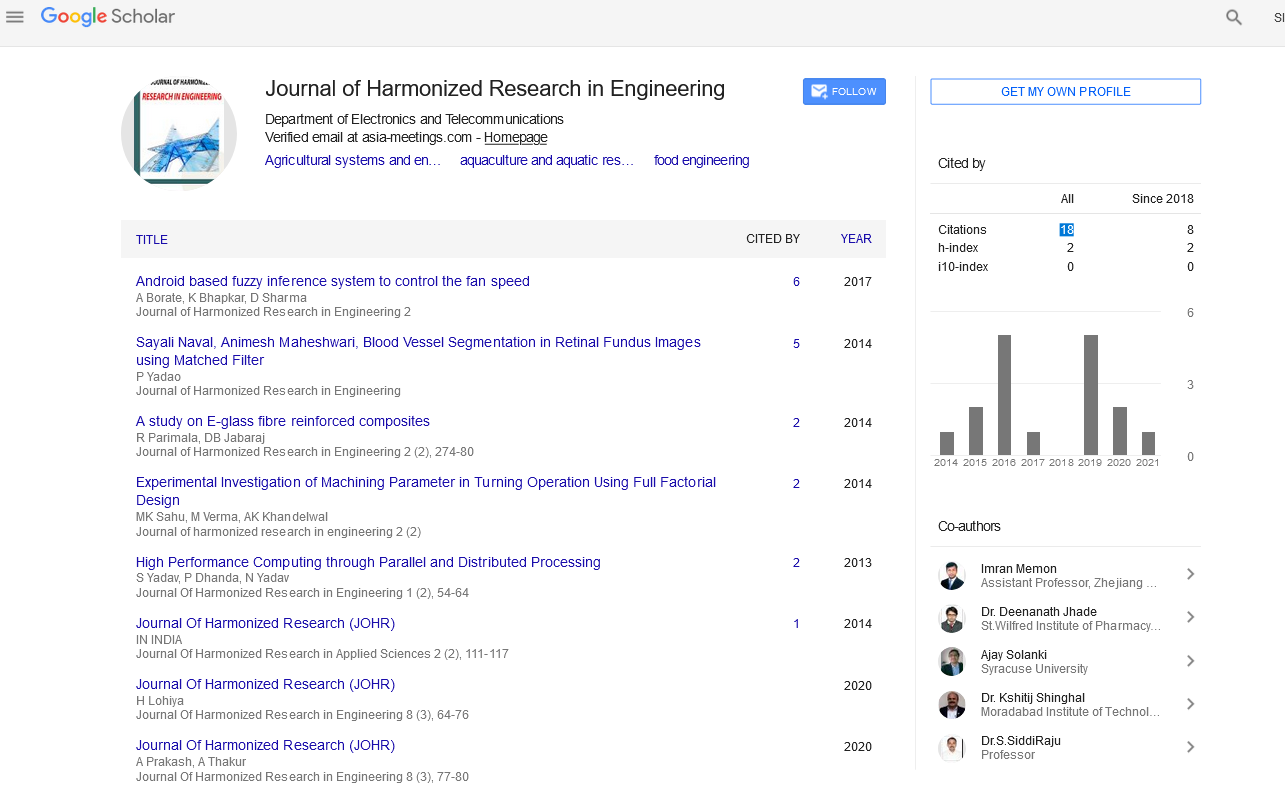

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report