PRODUCTION OF BIODIESEL FROM WASTE COOKING OIL: EFFECT OF POTASSIUM HYDROXIDE CONCENTRATION ON YIELD

Abstract

Author(s): Oji A, Tasieobi E.C, Evbuomwan B.O and Damingo E

The production of biodiesel from waste cooking oil (WCO) is one of the technological advances geared toward the promotion of clean energy sources. This conversion process deriving value fro m waste material also addresses the ecological and environmental concerns of waste management. Transesterification of waste cooking oil in the presence of Potassium Hydroxide accomplishes the conversion of WCO to biodiesel. Sensitivity analysis on biodiesel yield was performed at various catalyst concentrations of 0.75%, 1.00%, 1.25% and 1.50% (by mass of WCO) under identical reaction conditions of 60OC, reaction time of 60 minutes, 22g methanol and 100g of WCO. Catalyst concentration of 1.00% gave the maximum yield of 97.30%. Characterization of the biodiesel gave results which satisfied the American Society of Testing and Materials (ASTM) specification; density of 878kg/m3 at 15OC, kinematic viscosity of 4.70mm2/s at 40OC and flash point of 136OC. Biodiesel is suitable for use in internal combustion engines as alternative fuel to petroleum based diesel.

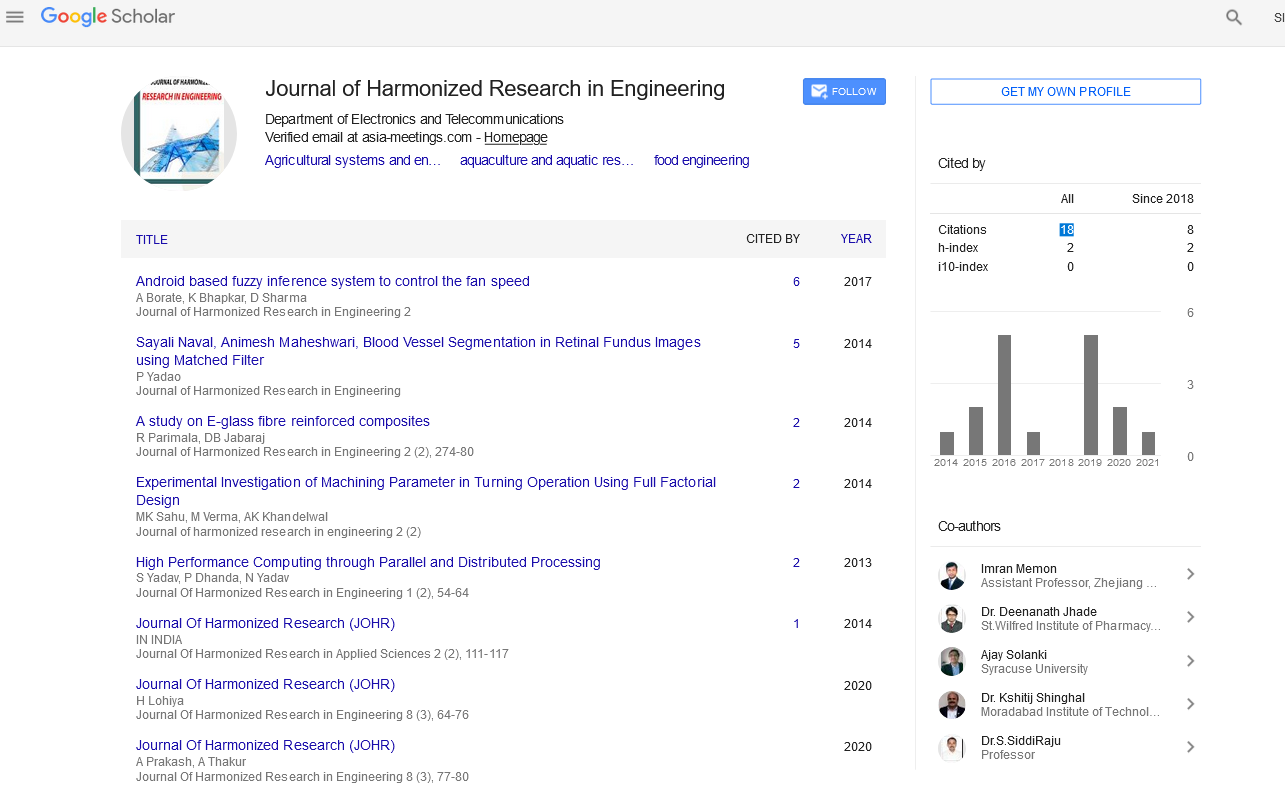

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report