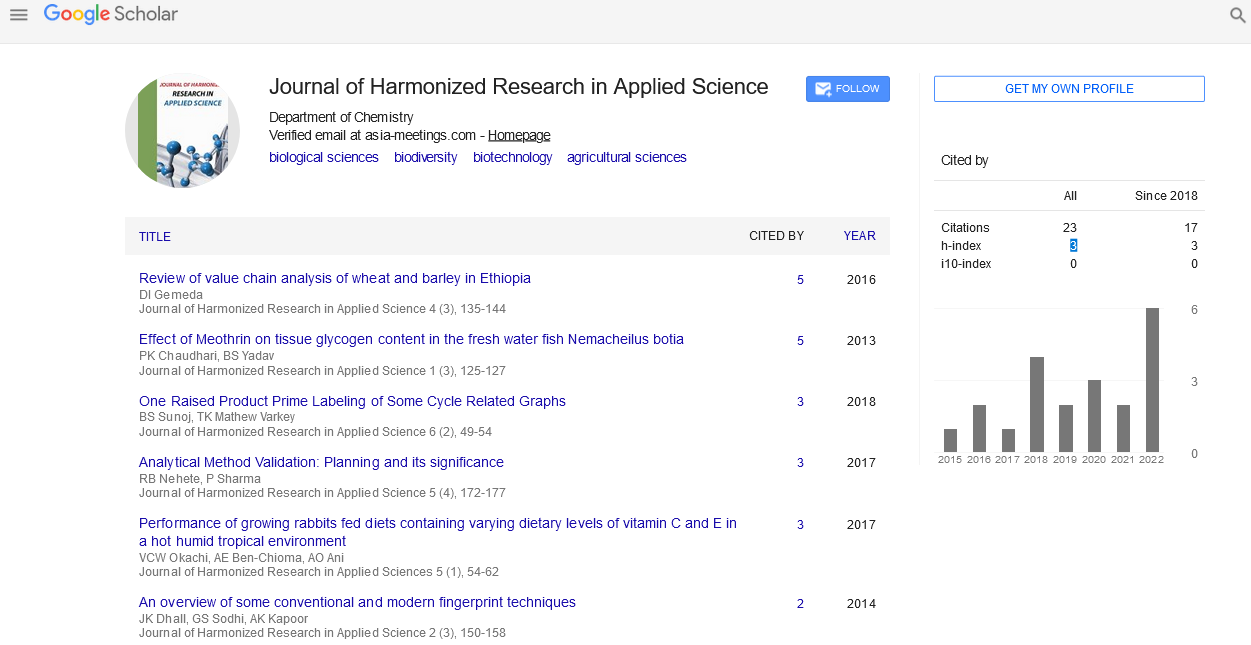

Opinion Article - (2022) Volume 10, Issue 2

SYNTHESIS OF NANO CELLULOSES AND THEIR CHARACTERIZATION

Georgina Mills*Received: May 30, 2022, Manuscript No. JHRAS-22-69071; Editor assigned: Jun 02, 2022, Pre QC No. JHRAS-22-69071(PQ); Reviewed: Jun 16, 2022, QC No. JHRAS-22-69071; Revised: Jun 23, 2022, Manuscript No. JHRAS-22-69071(R); Published: Jun 30, 2022, DOI: 10.30876/2321-7456.22.10.002.

Description

Since its first synthesis in the early 1900s, the invention of plastics has been a major milestone in the advancement of human life quality. Plastics have nearly replaced other materials such as wood, metals, and ceramics in most consumer-related applications due to qualities such as light weight, durability, resistance to corrosion by most chemicals, diversity of applications, ease of processing, low cost, and so on. Despite the numerous applications and benefits of plastics, the accumulation of plastic trash has been a major environmental concern since its inception. Plastic waste does not decompose in any way; it takes up land fill space or ends up in the ocean for hundreds of years after it is discarded. The majority of monomers needed to manufacture popular plastics such as polypropylene, polyethylene, and polystyrene are derived from fossil hydrocarbons. As a result, they accumulate rather than dissolving in the natural environment.

Nanocellulose materials have unique features and functionalities due to their nanosize, shape, and huge surface area, and these qualities open up various application areas previously thought unattainable for cellulose materials. Nanocelluloses potential applications includes adhesives, cement, paper, fluids, nanocomposites, films, cosmetics, paints, membranes, template for flexible electronic components, batteries, textiles, biomedical and tissue engineering scaffolds and more. Outstanding nanocellulose features, such as high on-axis stiffness, sustainability, biodegradability, scalability, and mechanical reinforcement potential, drive research and commercialization. As a result, nanocellulose is predicted to become one of the most extensively used nanomaterials in the coming years, as prices are likely to fall significantly as a result of a competitive market. Nanocellulose production and applications have grown in popularity due to its high strength, light weight, biodegradability, and renewability.

The two primary families of cellulose nanofibers are cellulose nanocrystal and nanofibrillated cellulose, which differ in size and crystallinity. Nanowhiskers, nanorods, and rod-like cellulose crystals are all terms used to describe Cellulose nanocrystals. The Cellulose nanocrystals is typically made by acid hydrolysis of cellulose fibres with a low aspect ratio, a typical diameter of 2 nm-20 nm, and a length distribution of 100 to 600 nm. NFC is also known as cellulose nanofibril or cellulose nanofiber. The smallest structural unit of plant fibres, nanofibrillated cellulose is made up of a bundle of stretched cellulose chain molecules and long, flexible, and entangled cellulose nanofibers with a diameter of about 1 nm-100 nm. Furthermore, various chemical and enzymatic pretreatments applied to the pulp prior to mechanical nanofibrillation are commonly used to favour fibrillation and reduce energy demand, resulting in a wide range of nanofibrillated cellulose with properties that differ from nanocrystal cellulose and mechanically produced nanofibrillated cellulose (also known as microfibrillated cellulose), making them appealing in a variety of industrial applications. Nano fibrillated cellulose have great mechanical strength, transparency, and chemical reactivity in general. The properties of NC, and therefore their characterization approaches, are greatly influenced by their manufacturing process (mechanical, chemical, or biological), cellulose source material (wood, pulp, recycled paper, bamboo, agro wastes, cotton, or other biomass sources), and final function.

Physical or chemical treatments of cellulose fibre are routinely used to make nanocellulose. Nanocellulose is gaining popularity because of its complicated architecture, which imparts a unique combination of stiffness, strength, and toughness, as well as the fact that it contains nanoscale constituents, such as high strength and modulus and huge aspect ratios. Natural availability, inherent renewability, biodegradability, and adjustable surface chemistry are all advantages inherited from cellulose. The growing demand for sustainable lightweight materials with superior mechanical qualities, particularly in emerging industries, has opened new ways for the development of nanocellulose-reinforced composites. There are three types of nanocellulose: Cellulose nanocrystals, cellulose nanofibrils, and bacterial nanocellulose. Cellulose nanocrystals are cellulose rod-like crystalline fragments from which the amorphous areas have been selectively removed using acid hydrolysis. Cellulose nanofibrils are filamentous fragments with crystalline and amorphous domains. Bacterial cellulose is a type of microbial cellulose generated by bacteria. On the surface of all forms of Nano cellulose are hydroxyl groups. They also contain anionic units (such as sulphate or phosphate esters) introduced during hydrolysis, which contribute significantly to their hydrophilic nature. While Nano cellulose’s hydrophobicity is a key asset for producing reinforced watersoluble polymer networks or structured hydrogel composites, it has made homogenous dispersion of nanocellulose in non-polar solvents and hydrophobic polymer matrices difficult.