ANALYSIS OF DEFECTS IN CENTRIFUGAL CASTING BY HYBRID METHOD

Abstract

Author(s): Aakanksha Suryawanshi and Shiena Shekhar

The defects of the centrifugally cast samples decrease the strength and quality of product, to reduce these problem randomly design the experiments has been used to analyses the influence of process parameters on centrifugal casting of aluminum alloy. Tests carried out on eight design of experiment characterized by different variation of Speed, Temperature and Type of cooling on aluminum alloy that solidify and analysis the defects of shrinkage and blow holes produce during cooling. The results of confirmation experiments reveal that grey–fuzzy hybrid method can effectively optimize an optimal combination of the process parameters.

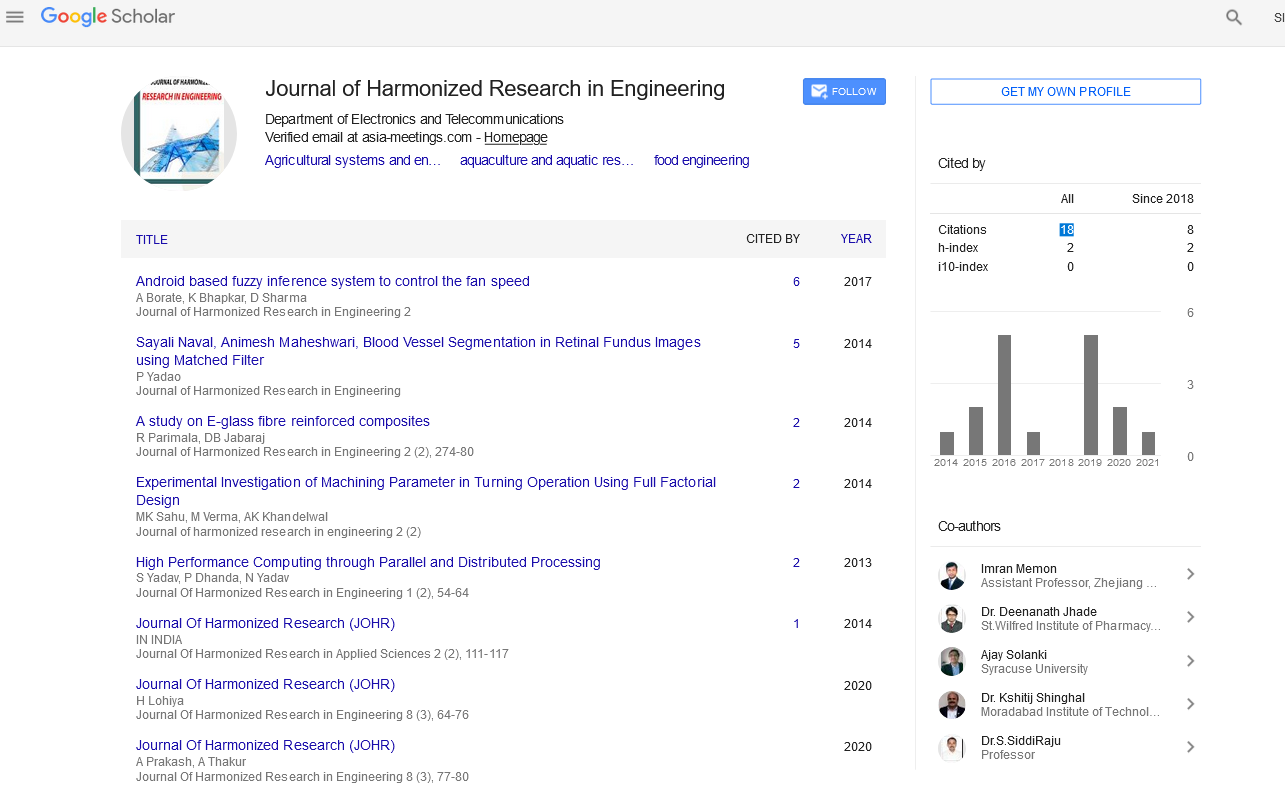

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report