EXPERIMENTAL INVESTIGATION OF MACHINING PARAMETER IN TURNING OPERATION USING FULL FACTORIAL DESIGN

Abstract

Author(s): Mohit Kumar Sahu, Manish Verma and Ashish Kumar Khandelwal

The purpose of this paper is to study the effect of speed, feed and depth of cut on Material Removal Rate(MRR) and cutting force (F c) in turning mild steel using high speed steel cutting tool. Experi ments were conducted on a centre lathe and the influence of cutting parameters was studied using analysis of variance (ANOVA) based on adjusted approach. Based on the main effects plots obtained through full factorial design use Design expert Software, optimum level for surface roughness and cutting force were chosen from the three levels of cutting parameters considered. Linear regression equation of cutting force has revealed that speed, feed, and depth of cut significantly influenced the variance. In case of material removal rate, the influencing factors were found to be feed and the interaction of speed and feed. As turning of mild steel using HSS is one among the major machining operations in manufacturing industry, the revelation made in this research would significantly contribute to the cutting parameters.

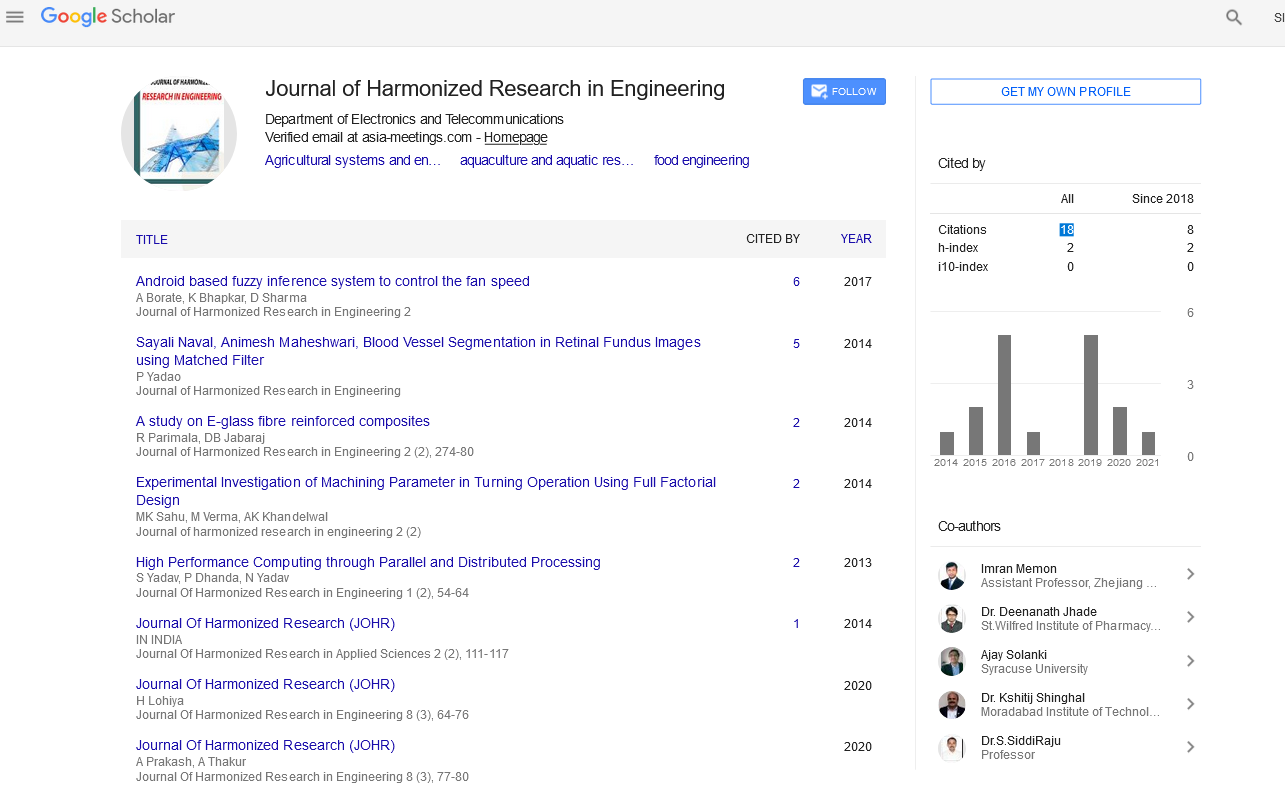

Google Scholar citation report

Citations : 43

Journal of Harmonized Research in Engineering received 43 citations as per google scholar report